Latest Projects

RHD Accelerator Linkage Restoration

(November 11, 2012)Over many years of use, most RHD accelerator linkages have worn heavily. Not only at pedal, but at each link through the system and it is these many links that the wear mutilplies to produce unresponsive pedal action, carb's that no longer open 100% and cables that are difficult to adjust correctly.

Within the cab area, there are several components to check. The pedal mechanism is made up of;

1. Pedal. (A H Schofield part number # B12A)

2. Pedal hinge. (A H Schofield part number # B14)

3. Pedal hinge pin. (A H Schofield part number # B14)

( There are actually two styles of pedal hinge pin available, the one shown below is the factory style with a machined recess that return spring sits in. Then there is the cheaper repro' pedal hinge pin version that has no return spring recess, instead it has a groove at each end for circlips to retain it )

4. Pedal hinge return spring.

5. Push rod. (A H Schofield part number # B13)

(Photo to follow )

Years of use wears the pivot hole on the pedal so the push rod is loose, wears the hinge pin so the pedal itself wobbles, the return spring breaks so the pedal doesn't return correctly and rattles. Often through rust on the cab floor, the pedal hinges become loose and break away from their factory welds. Then get bolted / rivetted / welded back in position, often out of alignment so the next part of the linkage is wrong.

Through the floor goes a push rod, with simple bent ends and circlips retaining it. Again these are a heavy wear point as there are no bushes used. Under the floor is the cross link. These too have no bushes in the design so it wears within its two mounts. Finally at the end of the cross link is the lever arm, this is held in position with a roll pin. Often the lever arm is not securely fixed to the cross link so again pedal action is lost before the accel' cable ever moves.

Typical wear on the cross link. Where the cross link rotates within it's mounts there is no bearing so the shaft wears as shown here.

At the pivot end, the push rod has worn the hole oval.

This wear allows the pedal action to be lost and become vague before the accel' cable even starts to move.

A solution to this has been worked on now. All UK made. New cross links are produced, exact copies of OG components then plated for corrision resistance, an improved push rod design and modified lever arm too are available.

Improved push rod design with sealed stainless steel ball joints to control the pivot action. (Seen here are pre-production plastic end fittings being used to testing purposes.)

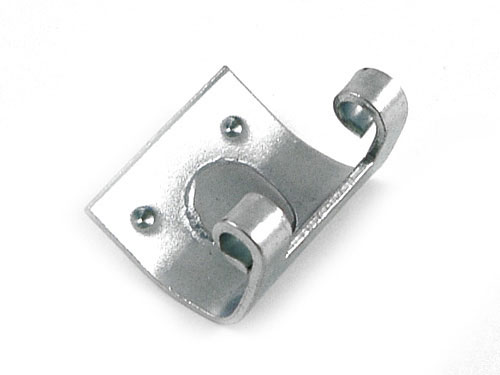

New cross link.

New pivot arm, extended length so to increase cable pull for use with twin carb's / twin throttle bodies.

Assembled components.